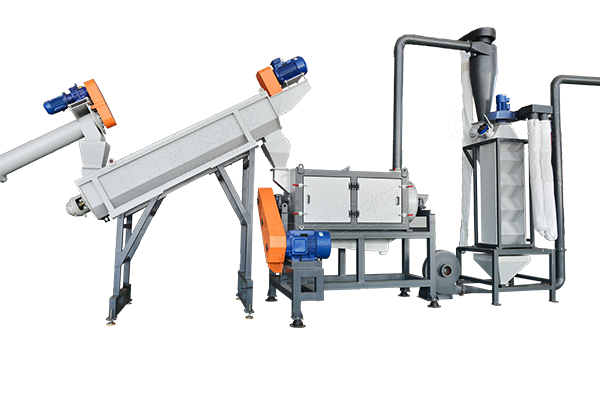

Centrifugal Dryer Dewatering Machine

The Boxin centrifugal dryer is purpose‑built to remove surface water from cleaned plastic flakes and films immediately after the washing process. By spinning materials at up to 2 000 rpm, it delivers rapid solid–liquid separation while consuming far less energy than thermal drying solutions.

Typical feedstocks include PET bottle flakes, HDPE regrind, LDPE film scraps, and even rigid sheet cut‑offs. Moisture is brought down to ≤ 8 %, allowing you to skip lengthy air‑drying tunnels and proceed straight to pelletizing or bagging.Get a Quote

How the Centrifugal Dryer Works

Material enters the perforated stainless‑steel basket via the top feed chute. A high‑torque motor drives the vertical spindle, generating tangential force that flings water outward through the screen holes while an air knife simultaneously blows away fine droplets. The integrated screw conveyor under the basket discharges dewatered flakes continuously, keeping residence time under 3 seconds and preventing heat build‑up or dust adhesion.

- Step 1 – Acceleration: VFD keeps start‑up torque smooth, protecting gearbox & bearings.

- Step 2 – Separation: Centrifugal force ≥ 800 G detaches water without damaging flakes.

- Step 3 – Air Assist: Dual nozzles create positive pressure to sweep moisture & fines.

- Step 4 – Discharge: Archimedes screw moves material toward the outlet chute for next process.

Key Benefits

- Energy‑efficient: Uses kWh ≈ 70 % lower than hot‑air dryers at equal throughput.

- Consistent moisture < 8 %: Ensures smooth extrusion and higher pellet clarity.

- Modular screens: Quick‑change design (3–5 mm perforations) suits flakes or film.

- Low maintenance: NSK bearings, automatic grease ports, and balanced rotor extend service life ≥ 40 000 h.

- Compact footprint: Vertical layout saves 30 % floor space compared with horizontal spinners.

Typical Applications

The centrifugal dryer is a standard component in Boxin’s Plastic Recycling Washing Line. It fits capacities from 300 kg/h pilot lines to 3 000 kg/h industrial setups and handles:

- PET flakes from post‑consumer bottles

- LDPE & LLDPE film fragments from shopping bags or agro‑film

- HDPE drum & cap regrind

- Rigid sheet or thermoformed scrap

How to Select the Right Model

Consider line throughput, particle size, bulk density, and target moisture level. The table below shows Boxin’s recommended ranges. Custom screen baskets (⌀ 700–1 000 mm) and motors up to 90 kW are available for high‑capacity needs.

Technical Specifications

| Parameter | BX‑CD700 | BX‑CD900 |

|---|---|---|

| Motor power | 45 kW | 75 kW |

| Spindle rotation ⌀ | 700 mm | 900 mm |

| Spindle length | 2 000 mm | 2 400 mm |

| Rotation speed | 2 000 rpm | 1 800 rpm |

| Throughput (kg/h) | 800 – 1 200 | 1 500 – 2 800 |

| Main body material | SUS 304 stainless steel | |

| Bearing | NSK sealed bearing | |

* Specifications can be tailored to match your existing washing line – contact our engineers for a custom proposal.

Case Study: Indonesian rPET Producer

After replacing two traditional hot‑air tunnels with a single BX‑CD900 centrifugal dryer, an Indonesian customer reduced energy consumption by 42 % and increased pellet clarity by 15 %. The payback period was calculated at 11 months.

Frequently Asked Questions

What is the minimum particle size the dryer can handle?

Thanks to interchangeable 3 mm‑to‑8 mm perforated screens, the dryer processes flakes as small as 4 mm without loss.

Does the machine generate dust?

An integrated cyclone separator removes airborne fines, keeping downstream areas clean and reducing filter load on pelletizers.

How often do we need to change bearings?

With automatic lubrication, NSK bearings typically last 18–24 months under 24/7 operation.

Ready to Dry Faster & Smarter?

Talk to our engineers and receive a tailored layout drawing plus ROI calculation – usually within 24 hours.Request Your Proposal