A PET bottle washing line is a specialized plastic recycling system used to recycle post-consumer PET (polyethylene terephthalate) bottles, transforming them into clean, recycled PET flakes.

After processing in our PET washing equipment, the cleaned new PET flakes can reach filament grade to food grade and fiber grade.

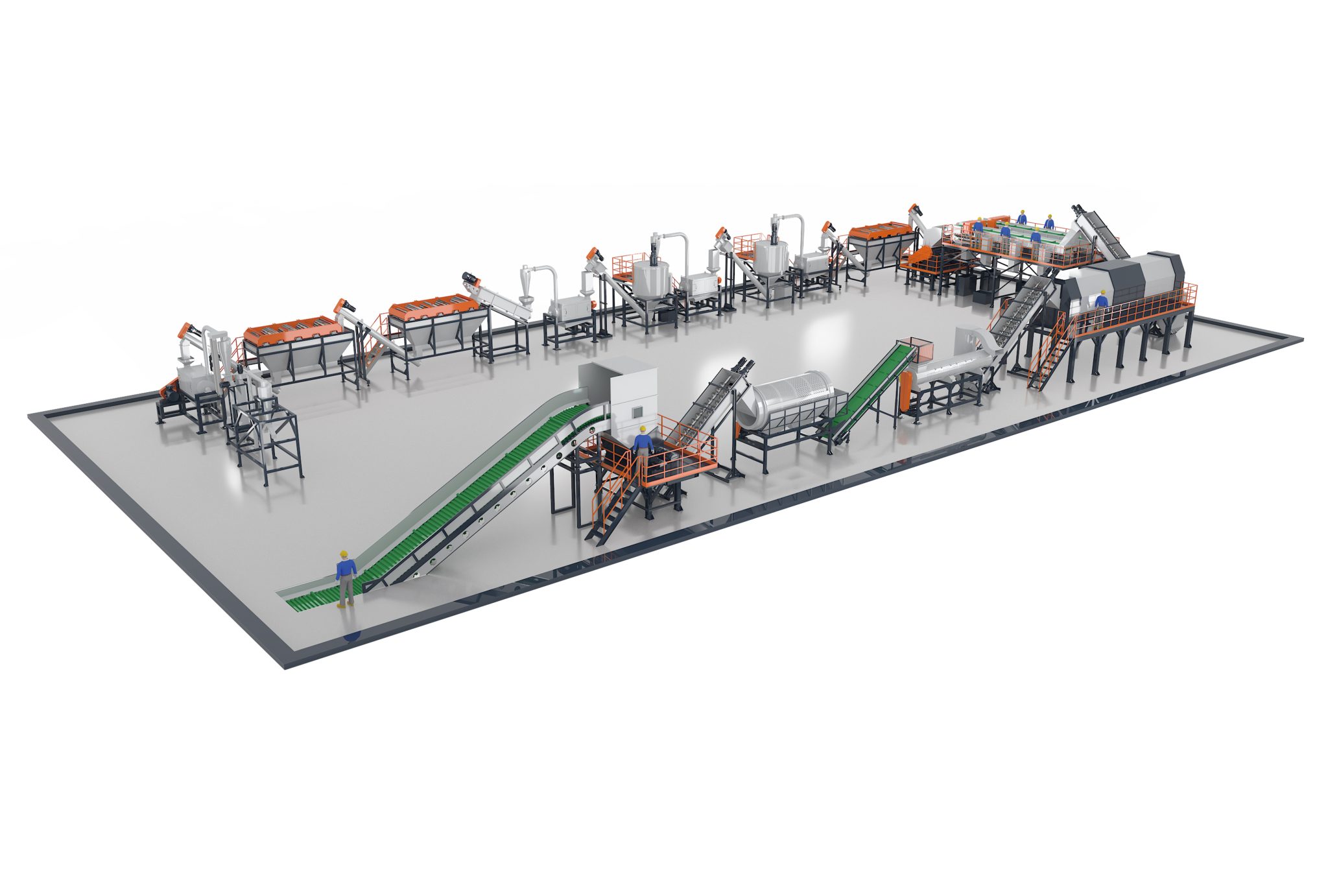

The contact PET washing equipment in Boxing is fully automated through the control cabinet and customized to the size of the customer’s plant.

Processing capacity:

500kg/H–5000KG/H or more

Energy Saving:

Customized water recycling lines minimize energy consumption and environmental impacts.

Modular design:

Modular to allow for expansion or upgrades as processing needs change

PET bottle washing line placement can be designed according to the drawing of the plant provided by the customer.

Provide construction guidance for water recirculation gutters

Degree of Automation:

Fully automated or semi-automated lines are available, and automation systems can include PLCs (Programmable Logic Controllers) to control and monitor the entire process.

Food-grade compliance:

For industries producing food-grade rPET, the line can be customized to include additional purification processes, such as IV (characteristic viscosity) maintenance, to ensure that the recycled material meets regulatory standards for food packaging.

20+ year old plastic recycling machine manufacturing plant, long lasting technical guidance

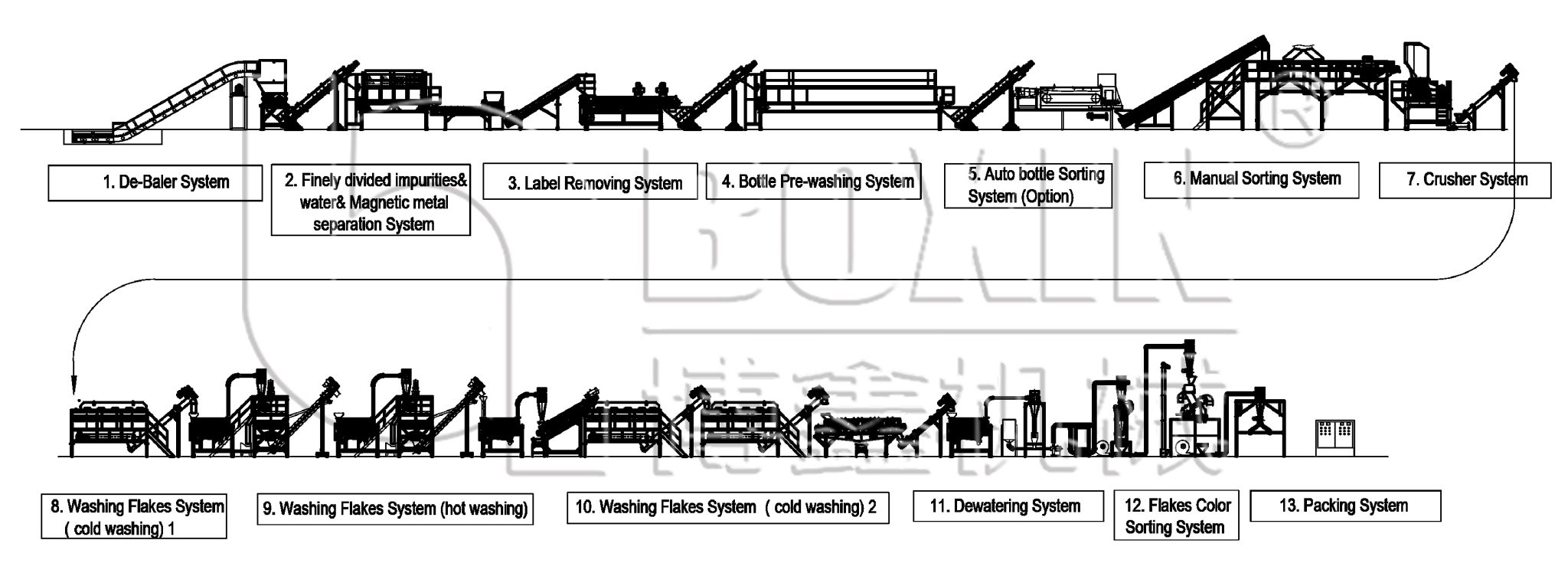

Debaler Machine to handle compressed PET bottle bales, the machine gently breaks down tightly compacted bales into loose individual bottles using rotating and vibrating blades for efficient feeding into the next stage of the recycling process.

A Trommel Separator consists of a rotating cylindrical drum. As the drum rotates, smaller contaminants fall through the perforations and are individually collected, reducing wear and tear on downstream equipment such as crushers and washers and improving overall efficiency.

Label Remover Machine uses friction to separate labels made of non-PET materials (e.g., PVC or PP) from plastic bottles to ensure the purity of the PET flakes without causing too much damage to the bottles themselves.

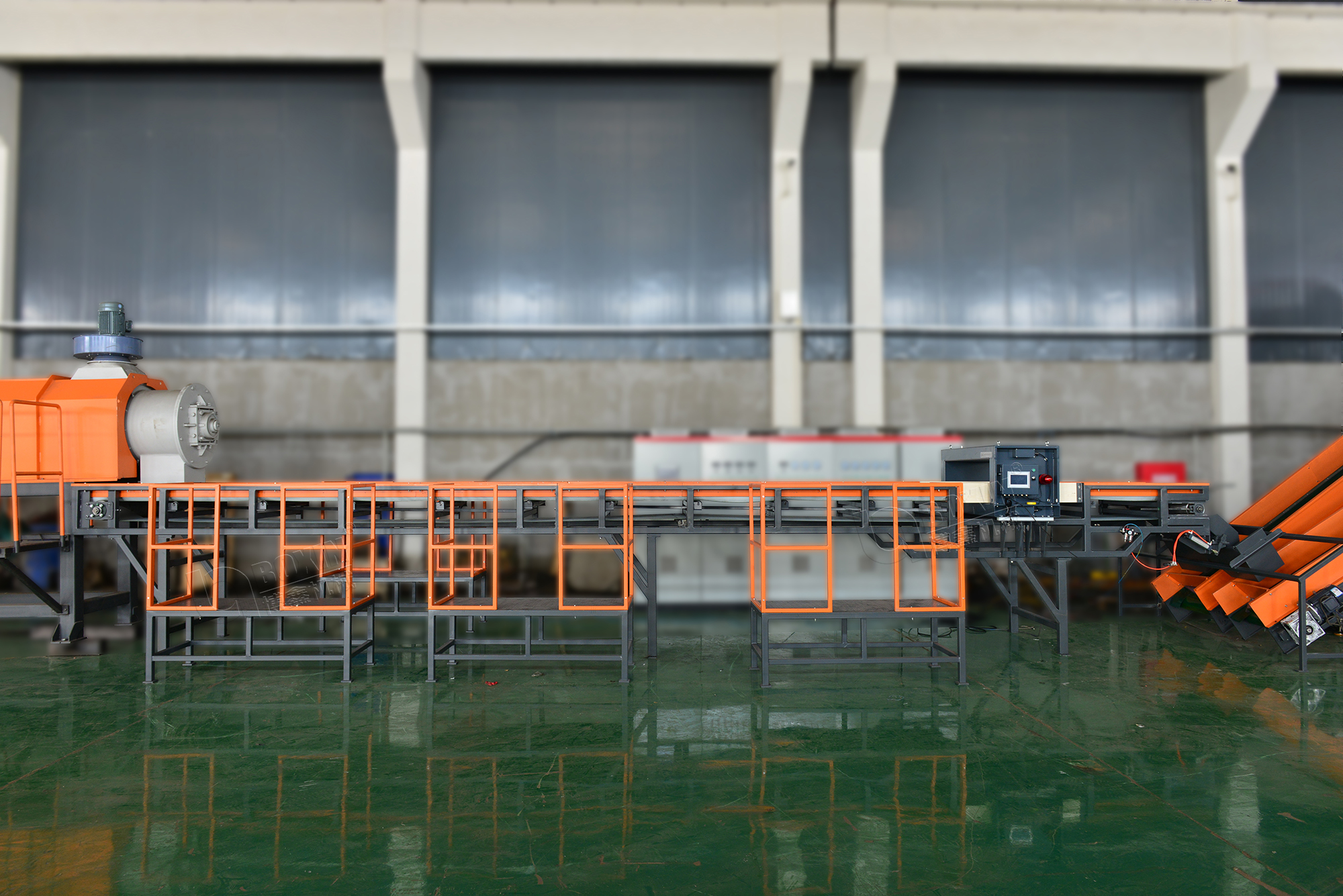

Manually sort out different materials and colors.

Detects metal and sends a signal to the control panel.Accurate metal detection: ≥ 2 mm

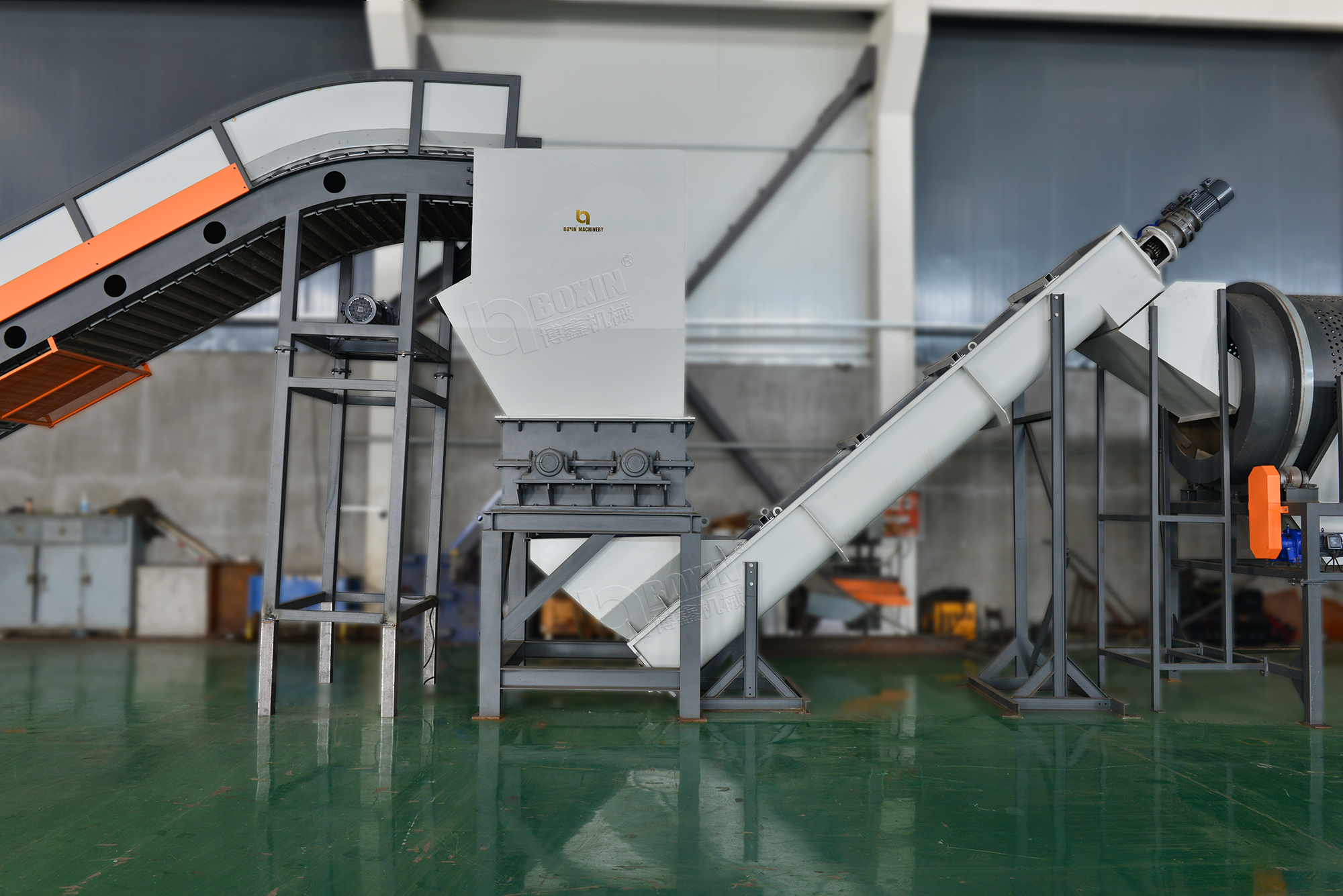

By continuously spraying water into the cutting chamber, The wet pelletizing process not only facilitates cutting and reduces frictional heat between the knife and the plastic but also pre-cleans the material.

This dual function is vital, as the process helps maintain the integrity of the PET material and contributes to the production of high quality recycled products.

Sharp, hard-wearing D2 pulverising blades cut bottles into small flakes through customised aperture screen sizes to achieve optimum dimensions, such as 8mm to 16mm.

Wet granulators play a key role in converting discarded bottles into a reusable resource and integrate seamlessly into the larger recycling workflow.

Sinking and floating separation tanks are a key part of the plastics recycling process, especially when dealing with mixed materials. The system uses water to efficiently separate materials based on buoyancy.

Materials such as plastic bottle labels and caps, which are usually made of PP or PE, float due to their low density. At the same time, the PET plastic of the bottles themselves is denser than water, causing them to sink.

At the bottom of the tank, a screw conveyor is strategically positioned. This mechanism collects the sinking PET materials and moves them to the next stage of the recycling process.

This high-speed friction washer is an indispensable recycling equipment for efficiently washing PET flakes.

It uses mechanical friction to tackle the most stubborn dirt and debris by rotating the spindle and adding cold water to rub the plastic flakes.

The hot washing system effectively removes glue used to apply labels and tackles stubborn residues such as leftover drinks and foodstuffs by using high temperature steam.

This thorough washing process not only ensures that PET flakes are sterilised, but also removes stubborn oil films and unpleasant odours. This equipment is essential for recyclers looking to increase the value of their PET flakes during the cleaning and recycling process.

Although the system runs on water only, the addition of specific chemicals can greatly improve its effectiveness. These detergents help to break down stubborn contaminants that are often difficult to remove with cold cleaning processes, ensuring that the recycled material is of the highest quality. The increased cleanliness and purity translates into higher value PET flakes.

The dehydrator uses centrifugal force at high rotational speeds to remove water and a large number of easily handled contaminants from the flakes through a screen.

This key role ensures that PET bottle flakes are ready for further processing with minimum water content and fewer contaminants. This reduces the burden on subsequent equipment operations.

Heating fans generate hot air to evaporate moisture. As the flakes pass through the stainless steel pipework, they are constantly agitated to maximise their exposure to the hot air and this constant interaction ensures uniform and efficient drying.

Once the moisture has been efficiently evaporated, a cyclone separator mixes the heated PET flakes with cooler air. This step stabilises the temperature of the flakes, prevents any thermal damage and prepares them for the next stage of processing.

The air classifier utilises the air flow and sorts the material. Lighter contaminants (paper scraps, plastic labels, dust) are removed while heavier PET flakes go to the next recycling stage.

By removing non-PET material early in the process, the air classifier minimises contamination, resulting in a higher quality end product.

The product silo serves as a caching container designed to safely hold clean and dry PET flakes. By caching the space in the silo, it allows continuous operation without downtime.

Moreover, the product silo provides organised storage, making it easy to manage and monitor material quantities.

PET flakes, which are usually used for the production of polyester fibres, can be sold directly or further converted into pellets. You can check out our PET flake pelletising machines.

The following is a brief description of the pelletising process:

Flake preparation: PET flakes need to be thoroughly cleaned and dried prior to extrusion. This ensures that any contaminants and moisture that may affect the quality of the final pellets are removed.

Extrusion process: The cleaned and dried flakes are fed into the extruder. Here, heat and mechanical forces melt and mix the material. Single-screw extruders are typically used for simpler applications, while twin-screw extruders are used for more complex compounding due to their enhanced mixing capabilities. parallel twin-screw extrusion is commonly used for PET pelletising.

Pellet Formation: As the material passes through the extruder, it is pushed through the die to form strands. It is then cooled and cut into uniform pellets. Pellets are usually cut in the form of water rings and draw bars.

Final Sorting and Quality Control: Quality checks are essential to ensure consistency and uniformity of pellet size and shape. Additional sorting equipment can be purchased to remove any non-conforming pellets.

By investing in the right equipment and following these steps, manufacturers can efficiently convert PET flakes into high-quality pellets, thereby expanding their usability in a variety of applications.

Model | Output (KG/H) | Installed Power (K) | Water Consumption(T/H) | Labor Requirements | Factory Area(L*W*H) |

BXA -500 | 500 | 2-3 | 2-3 | 4-5 | 70*6*5 |

BXA -1000 | 1000 | 3-5 | 3-5 | 4-5 | 80*6*5 |

BXA -2000 | 2000 | 6-8 | 6-8 | 5–6 | 90*7*6 |

BXA -3000 | 3000 | 10-12 | 10-12 | 6-8 | 100*6*6 |

BXA -5000 | 5000 | 12-15 | 12-15 | 8-10 | 120*8*6 |

Reference table of quality standards for bottles and flakes

moisture content | <0.9% |

PVC | <50ppm |

viscose | <10ppm |

PP/PE | <20ppm |

cooking oil | <20ppm |

tabs | <20ppm |

motley Flakes | <30ppm |

PH | Neutral |

Total impurities | <100ppm |

Bottle flakes size | 12mm, 14mm or according tocustomer needs |

Moisture Content: Maintaining a moisture content of less than 1-2% ensures that flakes remain dry and suitable for a variety of applications.

Bulk density: Achieving a bulk density of less than 0.3G/CM3 allows for efficient packaging and processing.

Impurity control:

Total Impurities: Keep below 300ppm.

PVC Content: Below 100ppm, critical for pet recycling.

Metal content: below 20ppm to ensure purity.

PE/PP content: below 200ppm to maintain high quality standards.

Granularity: The size range of the flakes is 14-16 mm, which can be customised to meet specific customer requirements.

These standards ensure that our PET flakes meet the high performance needs of our customers and provide a reliable option for manufacturing and recycling processes.

Our engineers (one electrical and one mechanical) will travel to your facility and install the washing line for you. We also offer routine maintenance teams as well as operations consultants that can ensure the PET recycling lines you purchase will run smoothly year and year.

Additionally, all recycling machinery comes with a limited warranty, providing you with peace of mind and assurance of quality. Our installation packages are designed to be comprehensive, with our engineers guiding you through the entire installation process.

This hands-on approach ensures that your team is fully equipped to operate the machinery effectively. To further enhance operational efficiency, we can arrange for routine maintenance and operations consultants. These services ensure that your PET recycling plant functions optimally, year after year.

All equipment from the Boxin pet bottle washing recycling line comes with detailed operation instructions and an installation guide. A list of required replacement parts will also be provided at the time of purchase. All machinery and parts are warranted against manufacturer defects and come with a 1-year limited warranty.

Our goal is to add value and exceed expectations for every project we develop