Small-scale plastics recycling plants are becoming increasingly popular as they provide a flexible and scalable solution for recycling plastic waste for local communities or small businesses. These plants are particularly suited to entrepreneurs, small businesses and developing regions that may lack large-scale recycling infrastructure.

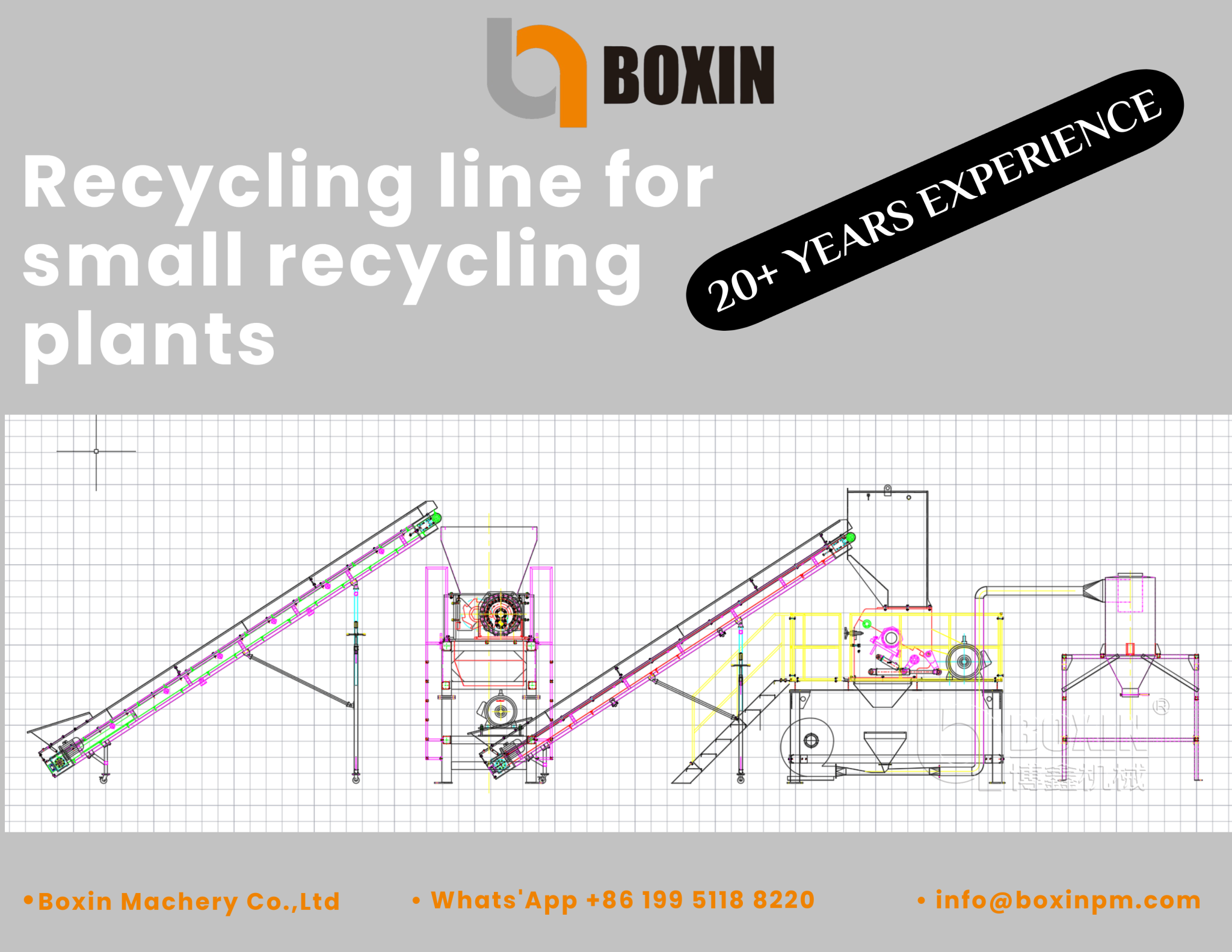

You only need five pieces of equipment: conveyor, metal detector (optional), crusher/shredder, blowing system and collection silo.

Smaller plants can process a wide range of plastic types for example:

PET: commonly used in beverage bottles, food containers and textiles.

HDPE: Commonly used in milk jugs, detergent bottles and pipes.

LDPE: commonly used in plastic bags, food wrappers and some bottles.

PP: found in yogurt containers, straws and bottle caps.

PS: Used in disposable tableware, CD cases and food containers.

It is often thought that PET bottles make up more of the waste plastic products, so recycling waste plastic bottles would be the backbone of a small plastic recycling plant.

However, plastic bottles are composed of many kinds of plastics, among which PVC heat-shrinkable labels are a point that cannot be ignored. If the whole bottle goes directly into the crushing system, the finished product after discharging will be composed of various materials, which greatly improves the difficulty of sorting and is difficult to sell.

The most recommended materials for recycling are drums, tubes, sheets, and other single products. These materials are usually large and highly recognizable.

There is nothing better than a waste baling station to set up a small scale recycling of waste plastics.

Usually, waste baling stations simply sort the waste collected from various places and send it directly into the compression baler for processing.

If the waste baling station does not carry out fine sorting, the rate of impurities in the whole bale is very high, and the added value of directly selling such bottles and bales is low, and the complaint rate of buyers is very high.

However, manual sorting will greatly increase the personnel cost, and the price of the sorted bottles and bales will be limited. Establishing a small-scale plastic recycling plant is the best choice.

Through manual sorting to reduce the inclusion rate of PET bottles and at the same time selecting barrels, tubes, sheets, and other single products through the plastic recycling system to be processed into flakes for sale, which greatly improves the profitability of the enterprise.

In addition, there is no better candidate for setting up a small-scale plastics recycling line than a manufacturer of various finished plastic products.

Examples include: preform manufacturers, plastic sheet manufacturers, blown film manufacturers, and so on. The yield rate of finished products of such manufacturers is usually 95%~98%, in which the edge materials or unqualified products will cause great waste if they are directly discarded or sold.

At this time, the establishment of a small plastics recycling production line can satisfy the self-circulation in the factory, which will reduce the operating costs of the enterprise in the long run. (This kind of recycling needs to be used together with granulator)

Generally, the production capacity of small plastic recycling plant is about 500-1000kg/h. Considering the upgrading of production line in the later stage, we don’t recommend the production capacity is lower than 500kg/h. Plastic recycling plant will usually increase the plastic washing equipment after making profit, and at this time, 1000kg/h~1500kg/h waste plastic washing and recycling line is the best production capacity.

Convey plastic waste to plastic crusher in bulk and efficiently.

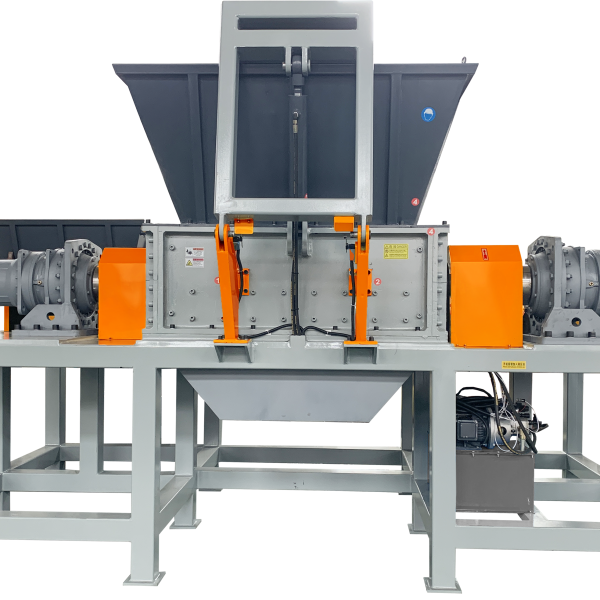

Used to deal with large pieces of raw materials such as: machine head material, chemical blue barrels, etc., if the processing of raw materials is smaller and lower hardness can be directly adopted crusher.

Processing plastic into smaller sheets (10mm~14), the finished size is determined by using different screen apertures.

The finished products are fed into the cache bin through the wind conveying system.

The metal detector can replace manual re-selection, when metal is detected, the metal detector will sound an alarm and stop the conveyor temporarily, reducing wear and tear of the crusher blades and reducing the sharpening cycle.

I'm the subject editor for Boxin Machinery and I've been working in the plastics recycling field for 15+ years .