As the global focus on plastics emissions management continues to grow, manual sorting platforms for pet bottles are critical to the efficiency of plastics recycling.

Advantages and challenges of manual sorting platforms for PET bottles

The introduction of a manual sorting platform for PET bottles brings the following advantages to plastics recycling:

- Improve sorting efficiency and significantly increase the recycling rate

- Reducing labor costs, reducing business pressure

- Realize the work volume, improve the sorting processing capacity

- Reduce the risk of manual injury and illness, and protect the safety of employees at work.

However, the platform also faces some challenges in practical application:

- Technical maturity: some platforms are still in development, and technical stability and sorting efficiency need to be improved.

- Sorting accuracy: the platform sorting accuracy is affected by material properties, pollution level, and other factors and needs to be continuously optimized.

- Manual assistance: Although the platform has automation functions, manual cooperation is still required for pre-sorting and subsequent processing.

- Environmental impact: the platform generates waste plastics and electronic emissions during operation, which need to be treated by the rainbow crowd to cause secondary pollution to the environment.

In summary, the PET bottle manual sorting platform for plastic recycling brings significant advantages. It improves sorting efficiency and accuracy but must overcome the cost, technical maturity, sorting accuracy, and other challenges before widespread popularization.

Deployment strategy for a manual sorting platform for PET bottles

When configuring a manual sorting platform for PET bottles, there are several key strategies to consider that will help optimize its efficiency and effectiveness:

Accurate Sorting

- Employing advanced sensor and image reject technology ensures that PET bottles are accurately sorted from mixed debris discharges to maximize recycling rates.

Intelligent Integration

- Integrates the platform with an emissions management system for automated data collection and analysis, providing instant information compatible with optimized platforms.

Proper Configuration

- Configure the platform in the right location based on the volume and composition of the release to ensure maximized recovery and cost-effectiveness.

Operational Efficiency

- Optimize the operational efficiency of the platform with automated systems and maintenance procedures to reduce labor costs and critical time.

Monitoring and Evaluation

- Set up a monitoring system to continuously monitor the platform’s condition, collect data to identify room for upgrading, and adjust the strategy when appropriate.

Personnel Training

- Provide appropriate training to staff to ensure adequate platform operation and maintenance procedures to maintain an efficient understanding of the stable operation.

conclusion

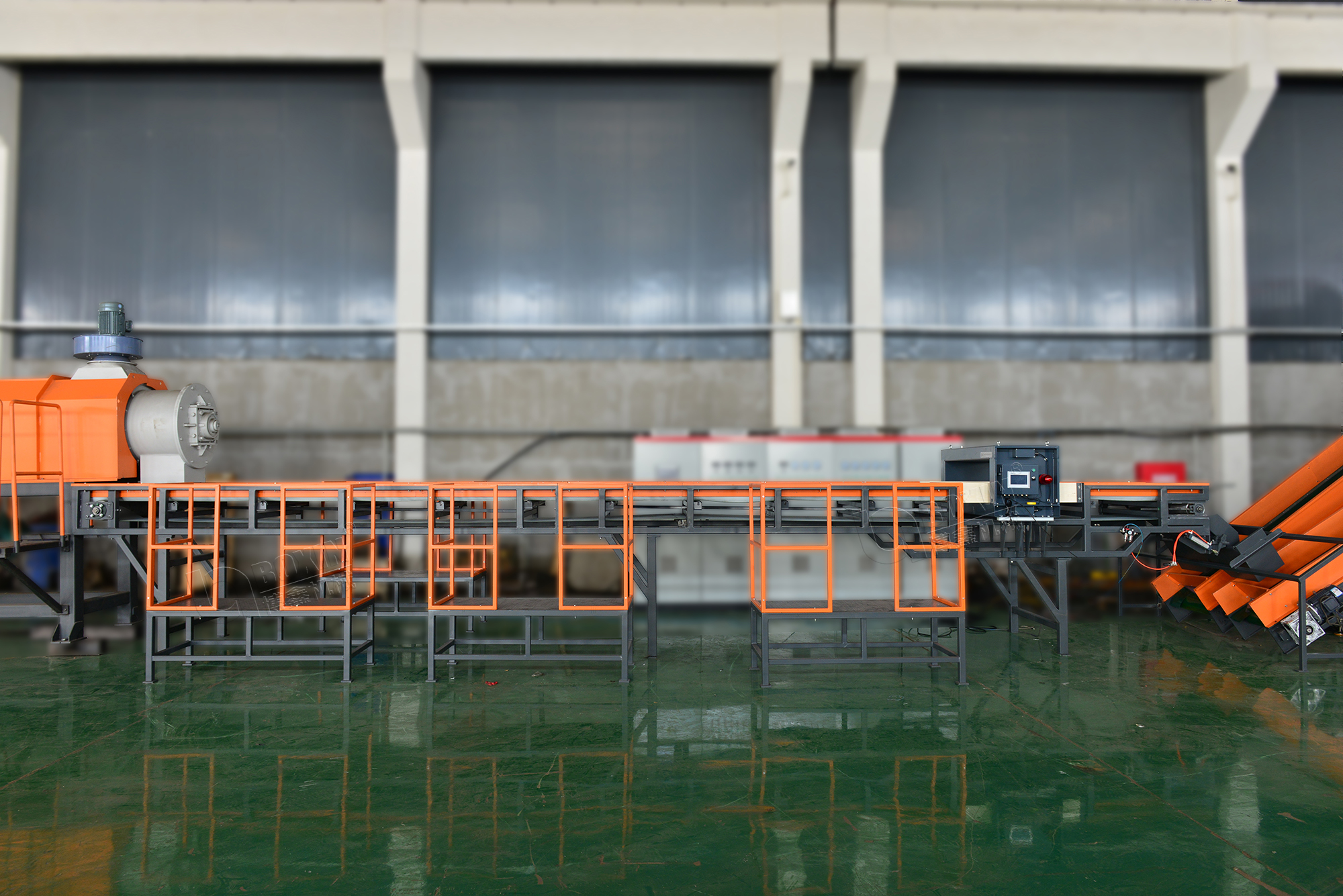

The emergence of manual sorting platforms for PET bottles has revolutionized the plastics recycling field, greatly enhancing the efficiency of PET bottle recycling and significantly contributing to the development of the circular economy. By adopting advanced machine vision, artificial intelligence, and other technologies, these platforms can accurately and quickly sort PET bottles, significantly reducing the need for labor and improving recycling quality. In addition, the intelligent optimization of the PET bottle manual sorting platforms and the application of AI technology have further enhanced their sorting capabilities, making plastic recycling more efficient and precise. The PET bottle sorting platform is expected to be widely used in various recycling fields in the future, contributing to creating a sustainable plastic cycle.

FAQ

What is the technical principle of the PET bottle manual sorting platform?

- PET bottle manual sorting platform adopts optical sensing, mechanical transmission, artificial intelligence, and other technologies to recognize PET bottles with different characteristics through sensors, and then robotic arms are used to sort them.

What are the advantages and challenges of the PET bottle sorting platform?

- Advantages: Improve PET bottle recycling efficiency, reduce labor costs, and improve material quality.

- Challenges: Higher equipment cost, regular maintenance, limited by bottle shape.

How does the PET bottle manual sorting platform utilize AI technology to improve efficiency?

- With AI algorithms, the platform can identify different types of PET bottles, such as colored and mixed-color bottles, and optimize sorting strategies to improve accuracy and processing speed.