As awareness of emissions management and recycling increases, material separators play a vital role in modern emissions treatment systems. These machines efficiently separate emissions based on the material’s physical, chemical, or optical properties, thereby increasing recycling rates and reducing environmental impact. Material separators have standard classifications and types, maximizing them with unique functions and application scenarios.

Screening:

Wind Sorting:

Gravitational sorting:

Magnetic Separation

Induction Separation

Eddy current separators utilize a rotating magnetic field to eject the conductive material. Different material separator types are available for different discharge streams, including solid waste and e-waste. By choosing the correct material separator, discharge management professionals can dramatically increase recycling rates, reduce environmental footprints, and promote sustainability.

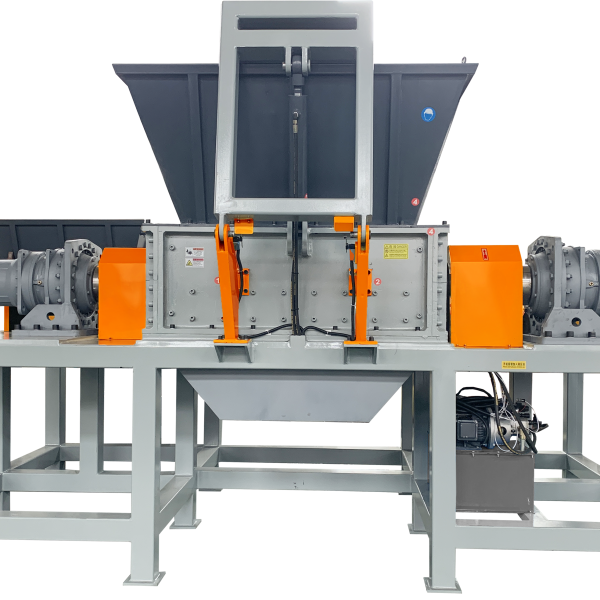

Convey plastic waste to plastic crusher in bulk and efficiently.

Used to deal with large pieces of raw materials such as: machine head material, chemical blue barrels, etc., if the processing of raw materials is smaller and lower hardness can be directly adopted crusher.

Processing plastic into smaller sheets (10mm~14), the finished size is determined by using different screen apertures.

The finished products are fed into the cache bin through the wind conveying system.

The metal detector can replace manual re-selection, when metal is detected, the metal detector will sound an alarm and stop the conveyor temporarily, reducing wear and tear of the crusher blades and reducing the sharpening cycle.

I'm the subject editor for Boxin Machinery and I've been working in the plastics recycling field for 15+ years .