Globally, Half of the plastic containers are produced (discarded after only one use). According to some sources, only 29% of these plastic bottles are recycled as post-consumer plastic, and many more are discarded and buried.

PET Bottle Recycling Line is mechanically recycled to produce high-quality food-grade bottle flakes by sorting, removing impurities, crushing, washing, and color sorting without affecting the physical properties of PET bottles.

Why Recycle Used Plastic Bottles Through PET Bottle Washling Line

PET plastic has excellent abrasion and friction resistance, dimensional stability and electrical insulation, commonly used in food containers, various packaging materials, electronic and electrical enclosures.

PET plastics are highly recyclable and are not only used for the direct sale of bottle flakes, but can also be made into pellets through pelletizing systems for textiles, bottle preforms, protective casings for electrical appliances that do not come into direct contact with each other, and so on. Great economic advantages

Despite the many valuable uses of pet recycling, we are addicted to single-use plastic products. But it takes more than 1,000 years for waste plastic to break down naturally, and waste plastic pollutants are now everywhere, not just in landfills, on the surface of the land, and in the oceans.

The use of mechanical recycling through Plastic recycle machine not only reduces the generation of waste pollutants, but also brings great economic value to the plastics recycling plant.

Importance of using PET Bottle Recycling Line

The production of PET plastics is a complex and energy-intensive process, requiring approximately 2 barrels of crude oil for every ton of PET produced. the PET production process generates greenhouse gases such as gas flotation and carbon dioxide and releases hazardous air emissions such as volatile organic compounds (VOCs), which can negatively impact air quality and human health.

Unreasonable disposal of PET plastics can damage oceans and habitats, affecting the feeding and reproductive behavior of species. PET plastics are corroded by seawater and break down into tiny particles (less than 5 millimeters) that persist in the environment, threatening the health of wildlife and human drinking water. When these tiny particles are recognized by marine organisms, the material bioaccumulates along the food chain, causing predators below to dissolve.

Use of chemical recycling: destroys the physical properties of the plastic, reduces the economic value of the recycled product, and can be hazardous to operate.

Using physical landfill: Direct physical landfill is not only a waste of land resources, but the physical decomposition time is usually up to 500 years or more, and the contaminated land cannot be directly farmed.

Incineration: Disposal of waste plastics by incineration is even more environmentally destructive. The decomposition of pet plastics through high temperatures produces trace amounts of toxic gases and releases carbon dioxide to destroy the ozone layer, and the process of incineration requires a large amount of heating materials, and the incinerated pet has no economic value.

Environmental Footprint of PET Plastics Production

The production of PET plastics is a complex and energy-intensive process that can have significant environmental impacts. Major environmental impacts include:

Crude Oil Consumption:

- PET plastics are made from crude oil, and it takes about 2 barrels to produce each ton of PET.

Greenhouse Gas Emissions:

- The PET production process produces greenhouse gases, such as gas rise and carbon dioxide, which can start climate change.

Air Pollution:

- PET production releases harmful air emissions, such as volatile organic compounds (VOCs), which can negatively impact air quality and human health.

Water Consumption:

- PET production requires large amounts of water and produces wastewater, which can cause water pollution if not treated.

Land use:

- Crude oil extraction and PET production facilities require large amounts of land, which can affect ecosystems and biodiversity.

Therefore, the production of PET plastics has significant negative impacts on the environment, and these impacts must be considered when assessing its environmental protection.

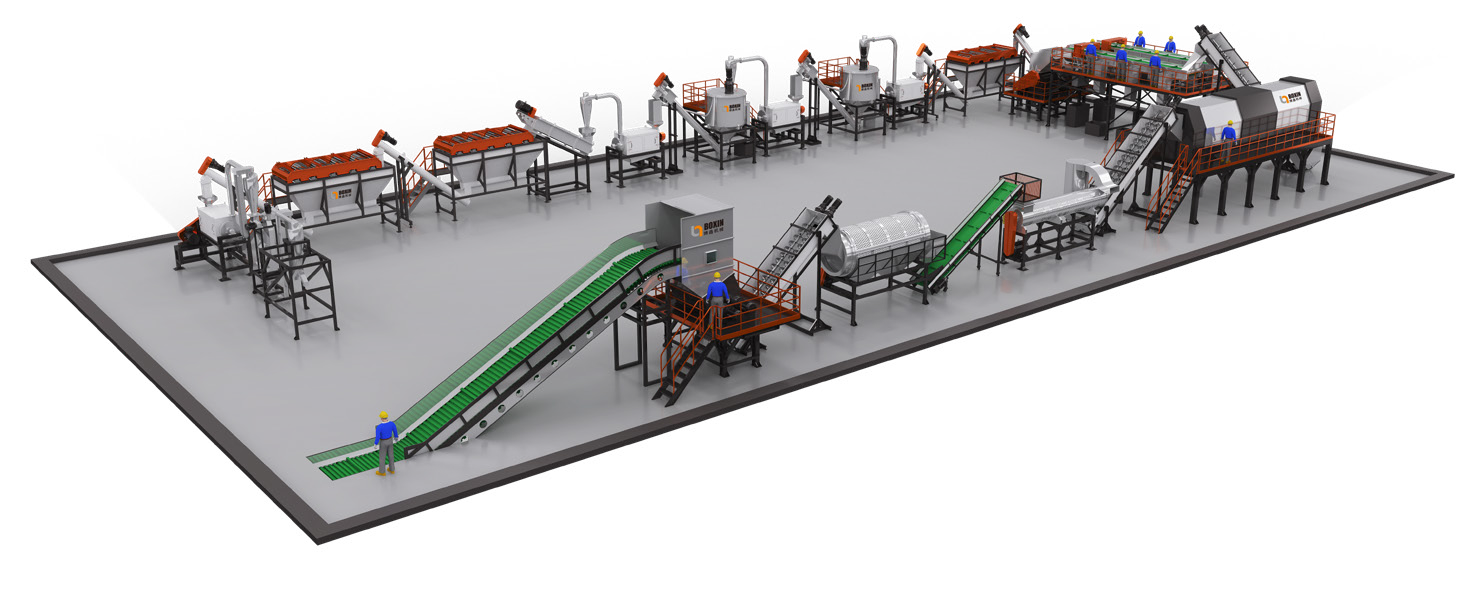

PET Recycling Line Mechanical Components

1. conveying system

The conveyor system includes belt conveyor, chain conveyor and screw conveyor, which not only reduces labor and ensures the safety of employees but also improves the quality of finished products.

2. Sorting systems

In addition to the basic manual sorting platform, boxin added electromagnetic sorting equipment, optical color sorting, and material color integrated machine to improve the quality of pet sheet.

3. Crushing Systems

Waste pet bottles into the crusher through the addition of water treatment can not only carry out the basic decontamination, reduce the generation of fine dust can increase the service life of the crusher blades.

4. Washing Systems

The selection of the cleaning system needs to be determined according to the degree of contamination of the material and the quality requirements of the final product. The system consists of pre-cleaning, cold washing, hot washing, friction washing, spray washing, through the combination of various equipment to achieve the finished product requirements.

5. desiccation

For pet flakes, a centrifugal dewatering machine is usually used in combination with a hot-air ducted drying system to further reduce the water content, and a label sucker is added to the system to ensure the purity of the flakes by varying the specific gravity of the bottles.

6. squeezes

Pet flakes do not need to be extruded, and after cleaning and drying the flakes can go directly into the pelletizing system. The materials that need to be extruded are film materials, through extrusion can further reduce the water content and reduce the storage space.

7. Pelletizing systems

boxing uses a parallel twin-screw pelletizing system designed specifically for pet bottles to further enhance the quality of the final pellet.

Customize Your PET Bottle Washing Line

The stability and durability of the production line is extremely critical for PET bottle recycling plants. The PET bottle recycling line is usually made up of a combination of 10-20+ pieces of equipment, and if one of the machines needs to be shut down for maintenance, then the whole production line will be in a state of shutdown.

With more than 20 years of experience in plastic recycling, boxin Machinery has plastic recycling lines in the Middle East, Europe, Africa and Oceania, and fully understands the environmental and policy factors in each region.

Specialized field

Through years of research and development, our production line can guarantee 12~16 hours of smooth operation under high loads from below 45℃ to above -20℃; locally thickened inner walls and wear-resistant materials are replaced in the wear-prone areas to ensure the stability of the equipment, and 30% of anti-clogging space is reserved at the inlet and outlet and the sewage discharge place to reduce the downtime for maintenance.

Multifunctional

Self-developed design to meet the needs of bundling bottles – bottle flakes – granules, multi-stage cleaning, and a variety of auxiliary machinery to meet the automatic weighing and packaging, fiber to food-grade bottle flakes standard.

PET Plastic Bottle Recycling Line: Industry Applications

Textile industry

- In the textile industry PET pellets can be used to make environmentally friendly fabrics such as recycled polyester fibers.

Packaging Industry

- The use of PET plastic pellets makes packaging materials lighter and reduces dependence on traditional crude oil resources.

containers

- PET pellets can also be used to produce a variety of plastic products, the most widely used for water bottles, containers, etc.