Our pet bottle recycling machine can convert dirty mineral water, pet plastic bottles, coke bottles, plastic milk bottles, and other waste PET plastic into clean PET bottle flakes.

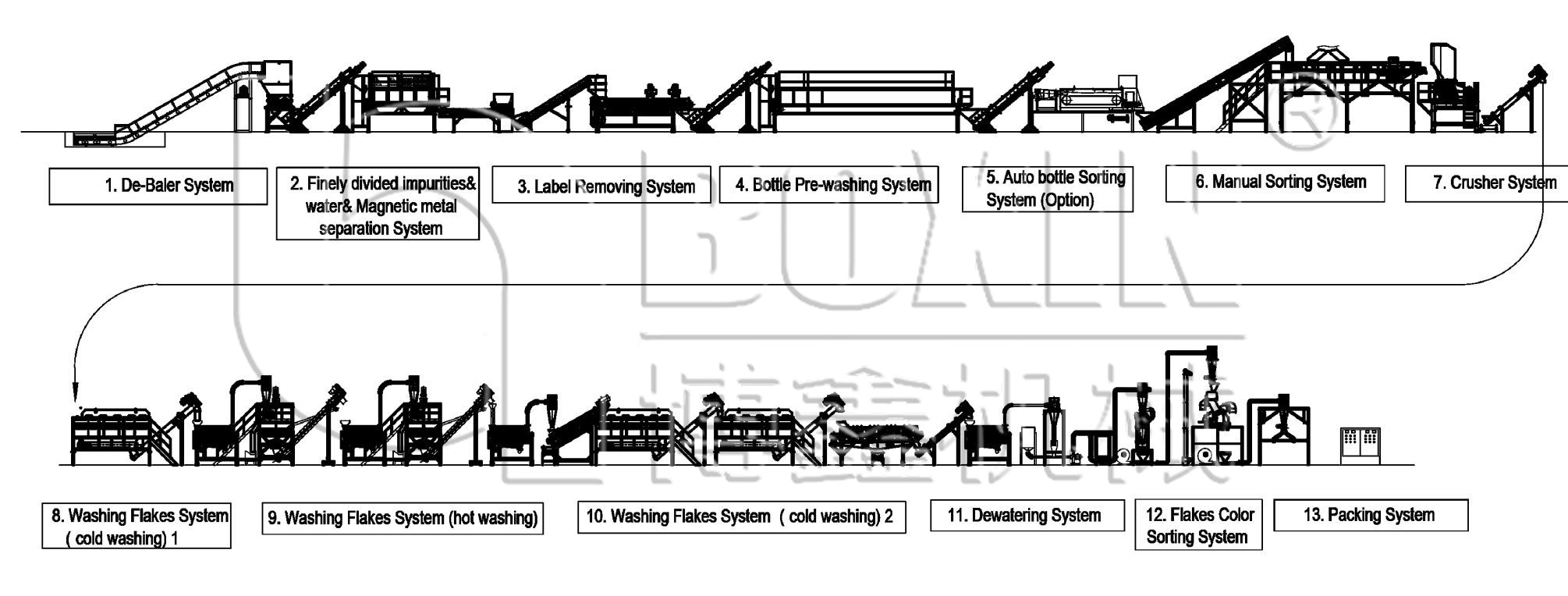

The recycling machine is fully automatic, and the washing process includes conveying, de-labeling, crushing, washing, drying, color sorting, and bagging. An electric control cabinet controls the whole recycling line.

Product Description

Pet recycling machines are advanced equipment for the circular economy of washing waste plastic. Through the PET bottles recycling plant, the washed plastic flakes can be fed into a granulator to be made into pellets, e.g., to make new-grade packaging Containers or other plastic products.

We offer a standard washing recycling machine from 500-5000 kg/h. Still, of course, as a Chinese supplier of washing and recycling machines for fiber to food-grade plastics with 20 years of experience in recycling, Boxin has a wide range of solutions for different levels of contaminated materials, such as multi-stage washing, additional color sorting equipment, metal removers, and so on. Depending on the plastic materials, line requirements, quality of the finished product, and budget control, We have the experience to provide customized solutions.

Working Process

Metal chain plate conveyor

You are conveying material to the next stop. (Magnetic separation can be added)

Unpacking machine

The unpacking machine opens the packed PET bottle bricks to loosen them.

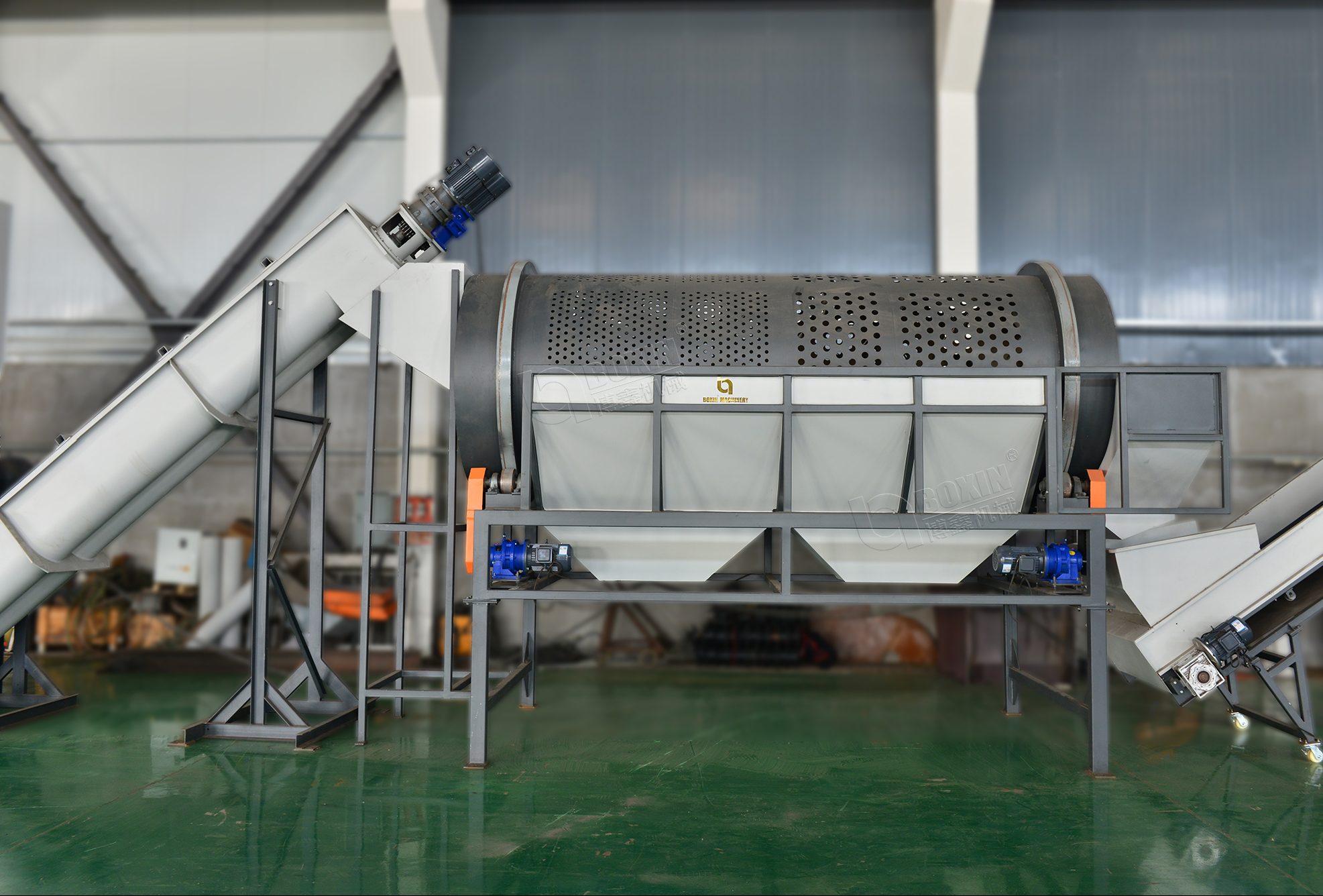

Three-drum screening machine

Separate different impurities, such as sand, stone, metal, and so on, according to the size of the holes.

Belt conveyor

You are conveying material to the next stop.

Off-labeling machine

For removing the labels by friction between the screen and arms

Manual sorting platform

Manually separate different materials and different colored plastic bottles.

crusher

Crush the bottles into flakes with the indicated size.

Floating washer

Remove labels, caps, and so on through fresh water.

High-speed friction washer

Through the injection of high-pressure water, the effective removal of chemicals and impurities.

High-speed de-watering machine

For reducing water content

Hot Washer

Flakes are stored in the tank mixed with hot water and chemicals. The rotary paddles make the flakes rub with each other to remove the dirt on the surface, such as glue, mud, and oil.

Storage silo

The flakes are sent to the storage silo by pneumatic force.

View other: Plastic Bottle Recycling Equipment

pet Bottle Recycling Machine Advantages

Variety of output

- 500-5000kg/h standard fully automatic recycling equipment.

- Customization for larger production volumes

Excellent finished product quality

- Up to 96%~98% label removal rate

- ADucted air drying system by adding a dehydrator, the dehydration rate of bottle flakes can reach 92%~96%.

- Increased equipment, finished product up to food grade

Self-developed crushing system

- Heavy-duty claw rotor, high-quality alloy steel welded structure, stress-relieved and dynamically balanced, solid, and stable in operation. No clogging, cooling system improves discharge quality and increases blade life, hydraulic opening, and closing reduce maintenance time.

Save water resources

- A water treatment system was added to reuse wastewater, and the water consumption per ton of the PET recycling machine was reduced to less than 1.5 liters.

Customized solutions

- Based on the material contamination level and finished product requirements provided by the customer, we add or reduce different small equipment so that the customer can purchase the most suitable plastic recycling machine at the most friendly price.

Optional equipment for your reference

- Metal removal washer: Improve the quality of finished products by magnetically adsorbing small metal objects

- Color sorter: Through advanced optical capabilities, it automatically sorts bottles of different colors, reducing labor and improving the quality of finished products.

- Label suction machine: uses a fan to suck in small label fragments and dust to improve the quality of finished products

- Multi-stage washing: specially designed for bottles with higher contamination levels

- Water treatment system: Reduce energy consumption and reduce secondary discharge of wastewater that pollutes the environment

Workflow And Technical Parameters

| Model | BXA -500 | BXA -1000 | BXA -2000 | BXA -3000 | BXA -5000 |

|---|---|---|---|---|---|

| Output (KG/H) | 500 | 1000 | 2000 | 3000 | 5000 |

| Installed Power (K) | 120-160 | 160-230 | 260-360 | 420-580 | 880-950 |

| Water Consumption(T/H) | 2-3 | 3-5 | 6-8 | 10-12 | 12-15 |

| Labor Requirements | 4-5 | 4-5 | 5–6 | 6-8 | 8-10 |

| Factory Area(L*W*H) | 70*6*5 | 80*6*5 | 90*7*6 | 100*6*6 | 120*8*6 |

Installation And Warranty

- If on-site installation instruction is required, Boxin will prepare a visa application for the engineers, who will go to the Buyer’s factory for the commissioning job. Engineers will give free training lessons to the laborers in the Buyer’s factory.

- Thirteen months for mechanical parts from the date of the bill of lading, providing online remote guidance or offline technical assistance in case of technical problems with the equipment(Including wearing parts or human damage and equipment downtime caused by improper operation). Boxin will charge the Buyer the cost price of spare parts after the equipment is out of warranty and provide a long-term technical guide.

FAQ

Can PET be 100% recycled?

- The common claims of “100% recyclable” or “100% recycled” made on PET beverage bottles are usually misleading or false.

How much does recycled PET plastic cost?

- now at an average of 53.72 cents per pound

How can I recycle my PET at home?

- Consumer recycling: To recycle PET plastic, you only need to collect, filter, sort, rinse

What are the methods of recycling pets?

- Via chemical and mechanical recycling