PET Bottle Washing Recycling Line, waste PP PE Film Washing Recycling Line, PP bag washing recycling line, and HDPE Hard plastic washing line.

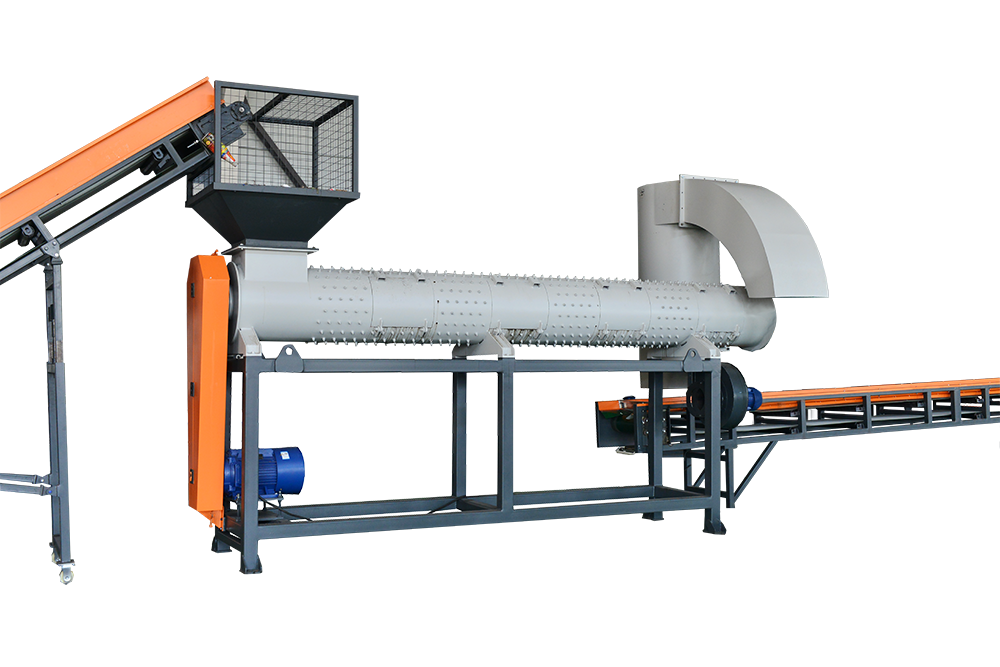

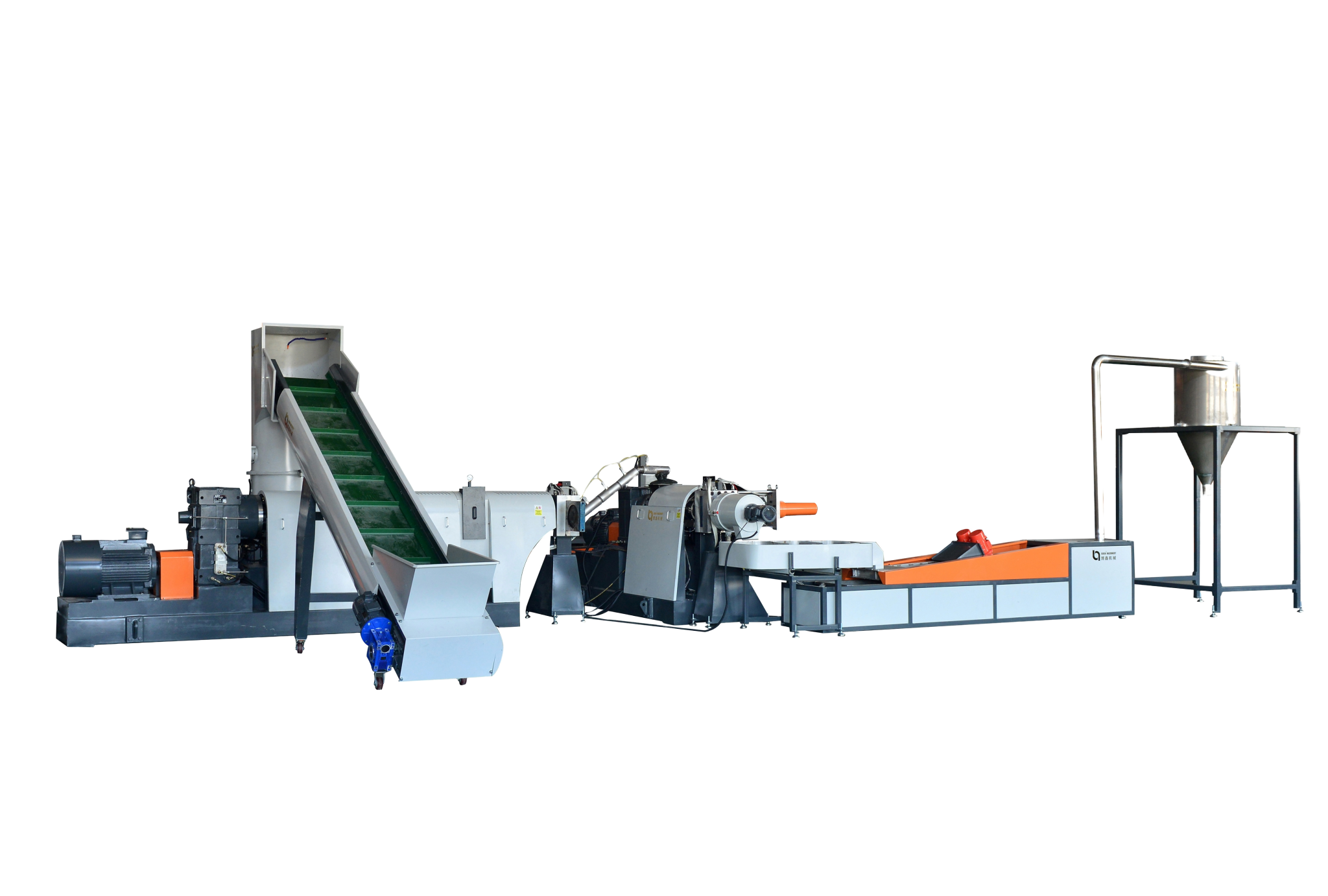

Our Scrap Plastic Recycling Washing Systems offer a complete solution for sorting, separating magazines, washing, and drying!

These lines start with scrap (large bales of raw material pre-processed at a scrap baling station) and end up with reusable abrasives or flakes for Sold directly or pelletized.

Boxin Machery’s plastic washing line is modular in design and can be customized to meet the needs of the customer, with a variety of patented designs that increase the removal of impurities without damaging the material at the production stage, and the final product is clean and dry enough to go directly into the pelletizing system and to work with water recirculation systems to reduce the amount of water used.

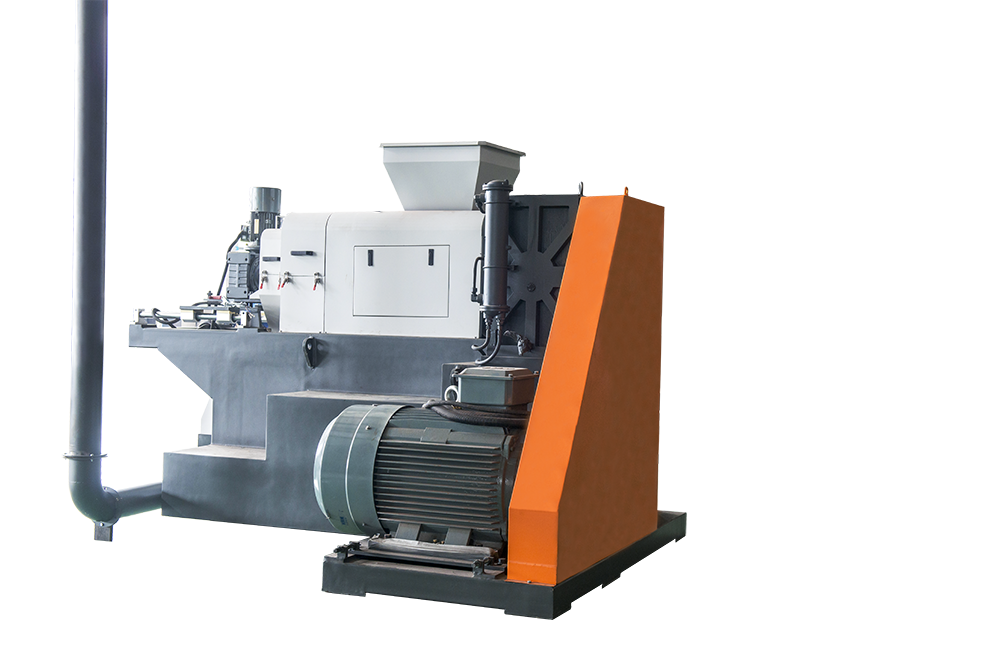

Boxin has not only plastic washing lines but also granulation systems and pelletizing systems for a broader range of plastic applications. This includes companies that specialize in recycling plastics, as well as companies that manufacture plastic products and recover resins from their own waste for internal use.

Our plastic washing machine can be found in the largest plastics recycling plants and the smallest plastics recycling plants. Post-consumer plastics recyclers, post-industrial plastics recyclers, and companies that recycle both consistently choose Boxin’s plastics recycling machines to improve profitability.

Boxin‘s Plastic Recycling Washing line recycling solutions for a wide range of plastics.

Boxin Plastic Crushing washing Pelletizing Recycling Systems offer a comprehensive one-stop solution for: runners, sprues, parts, cleaners, pipes, profiles, bags, bottles, packages, pails, drums, totes, woven fabrics, nonwovens, films, fibers, carpets, containers, buckets, IBCs, lids – in short, anything made of plastic.

It supports granulation only recycling, granulation washing recycling, granulation washing pelletizing recycling and direct pelletizing systems for processing into pellets.

Different materials, contamination levels of waste plastics, and final product requirements place different demands on the technology. Boxin is a one-stop shop for innovative technological solutions for the washing, recycling, and pelletizing of plastics.

PET bottle washing recycling line usually handles the following materials: pre-sorted PET bottle bale from the scrap baling station.

Boxin’s PET bottle washing lines not only meet the basic requirements for fiber-grade flakes, but with the addition of additional auxiliary equipment, the final flake grade can be food grade, grade 3A, with a moisture content of less than 3% and an impurity content of <100ppm.

Boxin also offers complete PET bottle washing pelletizing systems and Granulators systems (including, belt conveyors, metal detectors, silos).

PP / PE soft plastic washing recycling lines usually process the following materials: agricultural films, woven bags, etc.

Typically, waste plastic film is more than 70% contaminated with large amounts of sediment, glass, oil, etc., and the film is prone to kinking and tangling during the recycling process.

Boxin solves these problems by guaranteeing a high level of cleanliness and homogeneity of the final product and adding a new extruder that can be directly connected to the pelletizing system.

HDPE hard plastic washing and recycling production line usually handles the following materials: milk bottles, turnover baskets, chemical drums, etc.

The rigid plastic washing line is often also called a plastic sheet cleaning line. Rigid plastics are the easiest to clean and recycle compared to other waste plastics.

Because their physical properties are floating material, no additional auxiliary equipment needs to be added to process the clean sheet.

Profile sheet washing recycling lines typically process the following materials: long plastic tubes, tables, chairs, etc., that need to be pre-shredded.

This line is similar to the hard plastic washing line, except that it requires an additional shredder before entering the granulation equipment.

After the pre-processing of the shredder, the material is processed into large pieces of broken material and then into the crusher for finishing, which not only reduces the crusher’s work intensity but also improves the cleanliness of the finished product.

For more information or to arrange a trial run, please call (+86) 199 5118 8220