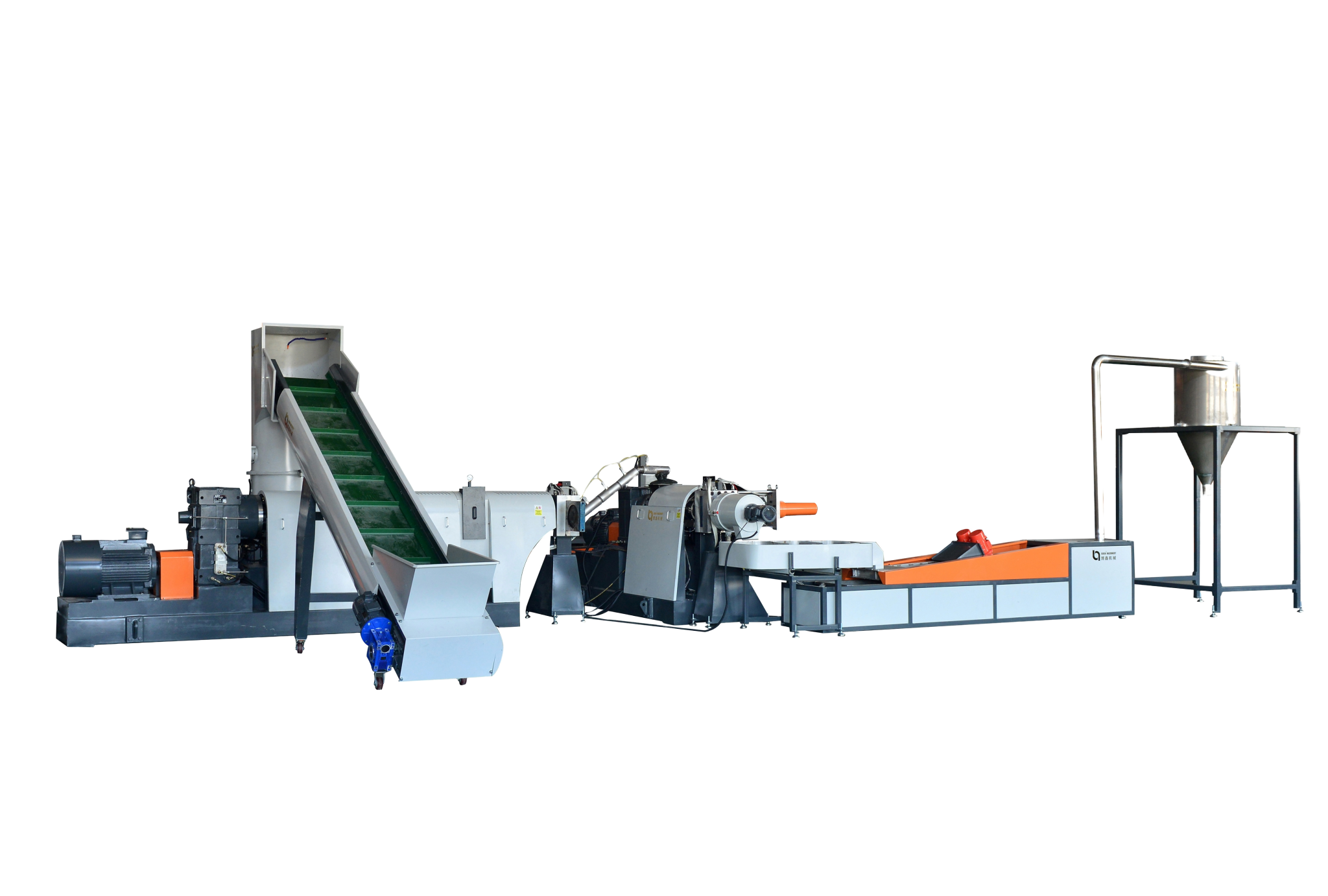

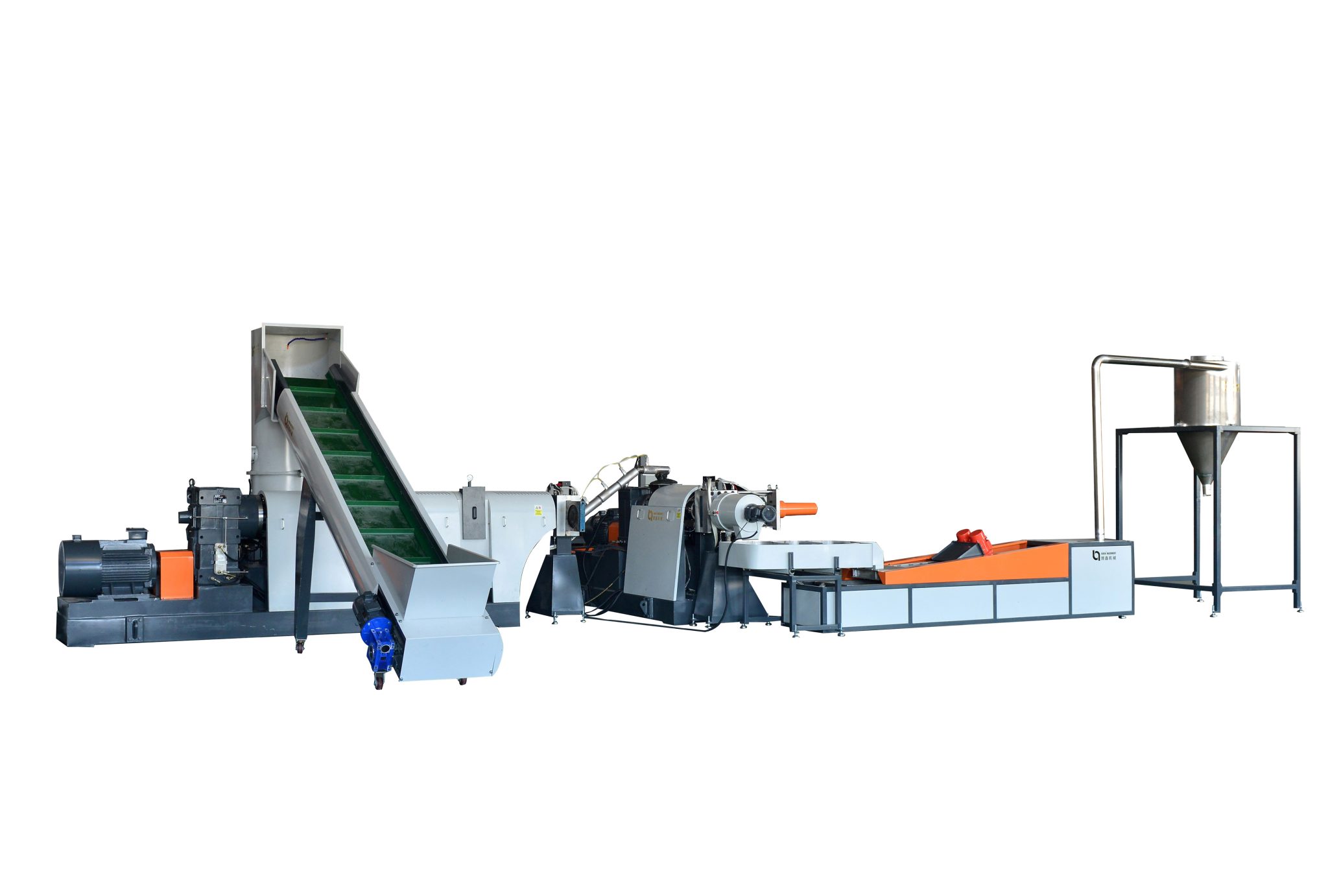

Boost Your Recycling Efficiency with Our Plastic Pelletizer Machines

Boxin’s plastic pelletizer machines are engineered for recycling various plastic waste materials—PE film, PP woven bags, PET bottle flakes, and more. Our systems ensure high output, low energy consumption, and uniform pellet quality, making them ideal for modern recycling lines.

Whether you’re processing soft plastics or rigid regrind, our pelletizing solutions can be tailored to your specific needs.

Plastic pelletizing is the final and most critical step in the recycling process. Once plastics are washed and crushed, turning them into uniform pellets allows for:

Easier downstream processing such as injection molding or extrusion

Consistent material quality for manufacturers

Higher resale value and transport efficiency

Standardization of recycled output for global trade

Boxin’s pelletizing systems ensure that your recycled plastic reaches a form that’s market-ready and industry-compliant.

At Boxin, we offer a range of plastic pelletizer machines designed to meet different production capacities, materials, and pelletizing styles. Whether you are processing soft LDPE film or hard PET flakes, we have the right solution for you.

-900x280.png)

The plastic pelletizing process involves melting, filtering, and reshaping plastic waste into uniform pellets. Boxin’s pelletizer systems follow a streamlined and energy-efficient workflow:

Feeding – Clean, dried Recycled plastic material are fed into the Feed inlet .

Plasticizing – Material is melted and homogenized under controlled temperature.

Filtration – Impurities are filtered using a melt filter or screen changer.

Pellet Cutting – Melted plastic is cut into pellets using one of the following:

Strand Cutting

Water-Ring Pelletizing

Underwater Pelletizing

Cooling & Drying – Pellets are cooled, dried, and collected for packaging.

Our plastic pelletizer machines are designed to handle a wide range of post-consumer and post-industrial plastic waste. Whether you’re recycling films, flakes, or rigid materials, Boxin has a solution that delivers consistent pellet quality.

Our systems are capable of processing both soft and rigid plastics, with pre-conditioning as needed.

👉 Have a specific material in mind? Contact our team to verify compatibility

Once processed by our pelletizer systems, recycled plastic pellets become valuable raw materials for various manufacturing industries. These pellets offer cost efficiency, material consistency, and help meet sustainability goals.

🏭 Common Applications:

Injection Molding

➤ Production of buckets, containers, automotive parts, and household goods

Blow Molding

➤ Bottles, drums, tanks, and chemical containers

Film Production

➤ Garbage bags, shrink films, packaging film

Pipe & Profile Extrusion

➤ Water pipes, conduits, window frames

3D Printing Feedstock (for select pellet quality)

📌 Depending on the material and processing method, recycled pellets can be tailored to meet specific industry standards.

A plastic pelletizer converts melted plastic into uniform pellets that can be reused in manufacturing processes such as injection molding and extrusion. It’s the final step in a recycling line.

A granulator is used to cut large plastic waste into smaller flakes, while a pelletizer is used to melt and reshape those flakes into pellets.

👉 They work in different stages of recycling.

Our machines can process PE, PP, PET, HDPE, LDPE, PS, ABS, and more. Soft films, rigid regrind, and bottle flakes are all supported with the right configuration.

Yes. Pellet size and shape can be adjusted by changing the die plate design, blade configuration, and pelletizing method.

Boxin pelletizers are available from 300 kg/h to 2000+ kg/h, depending on the model, material type, and production requirements.

Absolutely. We provide turnkey pelletizing systems, including feeding, extrusion, cutting, cooling, drying, and control systems.

Ready to Pelletize Your Plastic Waste Efficiently?

Boxin’s plastic pelletizer machines are trusted by recyclers and manufacturers worldwide to turn waste into high-quality, high-value plastic pellets.

Whether you’re handling soft film, rigid containers, or bottle flakes — we’ll help you design the right pelletizing solution for your material, budget, and output target.

📩 Let’s build your pelletizing system today.

👉 Get a Quote

📞 Or message us on WhatsApp now → Chat with us