For many rigid plastics recycling operations, the feedstock typically arrives at the plant in bundles of material that are compacted and bound to the plant by metal wires. In order to process this plastic stream in a recycling machine, these bundles must first be broken down.

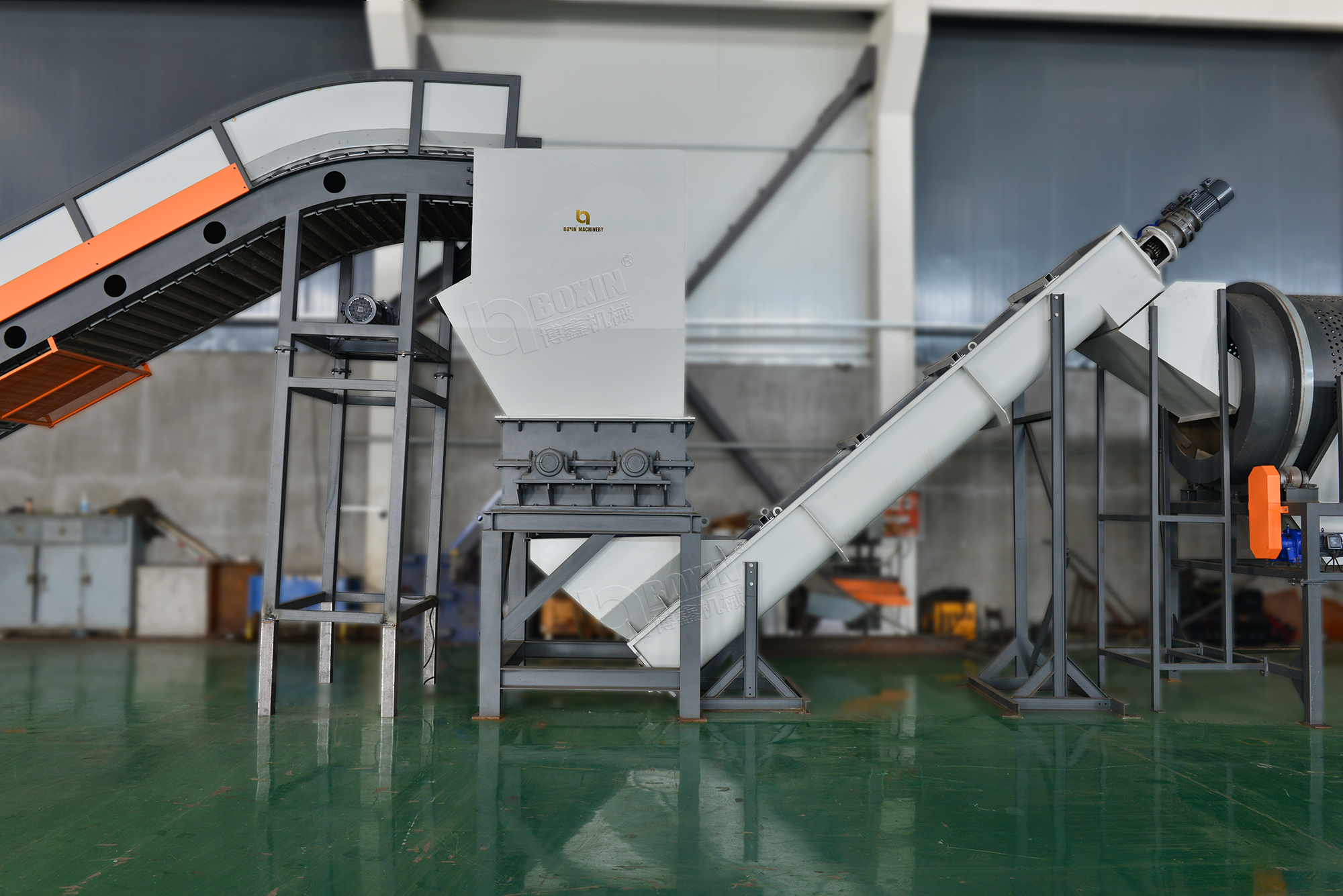

Debaler Machine are usually integrated with chain conveyors. All you need is a forklift to push the material into the chain conveyor and manually cut the strapping by hand, and the material is transported in an organised manner to the inlet of the Debaler Machine

Integrating this state-of-the-art machinery into your recycling line transforms manual labour into a seamless, automated process that significantly increases throughput. Not only will it optimise your operations, but it will also increase overall productivity.

Rotating diameter: φ500 mm

Rotating length: 1500 mm

Totally enclosed bearings

Saving on labor costs

304 stainless steel

The Debaler Machine adopts four shafts to break up and disperse, with multiple rows of hook claws on each shaft. By driving the knife claws through the main shaft will hook the material and make the material scattered.

The chassis is made of heavy-duty steel to withstand the stresses of breaking down large, tightly bound bales.