Plastic pelletizing is a system and technology that recycles waste plastics into reusable raw materials by (melting, extruding, agglomerating, extruding, cooling, pelletizing).

Plastic pellet manufacturers or recycling plants can then sell them directly or reuse them in various applications (the apparel industry, construction materials, chemical industry, agriculture, etc.) or even close the loop with their own production lines to become self-sufficient.

Working principle of plastic pelletizing machine

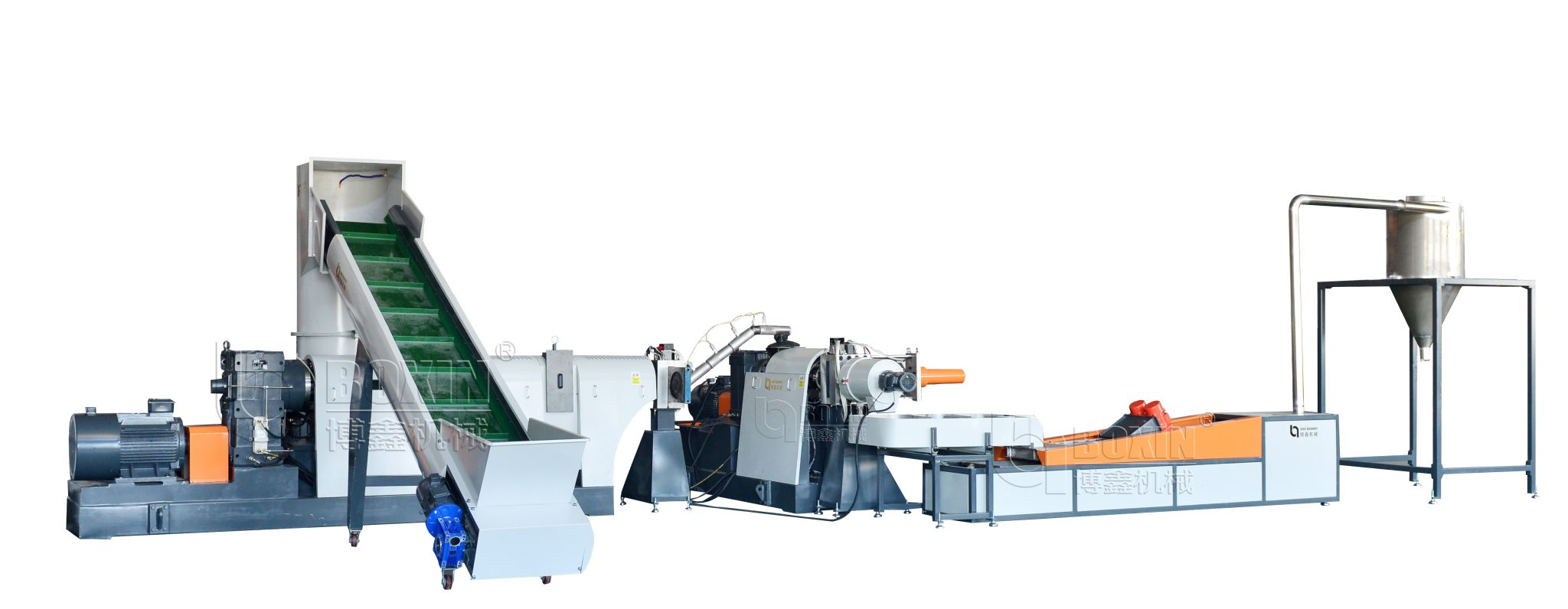

The plastic pelletizing system mainly consists of conveying, crushing, compacting, drying, extruding, changing the screen, filtering, Cutting grain, and controlling the electric system.

Plastic waste is transported to the compaction bin (with frequency control) through the feeding device, and the dynamic knife crushes the waste and generates friction heat, pre-drying the waste and pre-shrinking it through the infeed chute. The dried material is fully melted and plasticized by the specially designed screw and enters the water ring cutting step, and finally enters the dewatering vibration device for the collection of finished products.

High-quality plastic particle output is achieved by using the latest non-stop screen change technology.

Advantages of Boxing plastic pelletizing

Better pellet quality: Precision die heads and pelletizing systems are used to produce uniform pellets, which are filtered through a vibrating screen to achieve high quality.

Lower energy consumption: The use of variable frequency drives and high-efficiency cooling systems further reduces power consumption.

Durability and Reliability: A full set of stainless steel, unique chrome-plated and chrome-welded double-alloy screws, and the use of a non-stop screen changer not only ensures long-time operation of the equipment but also reduces downtime and maintenance costs.

Intelligent temperature control system: the sensor monitors the running status of the equipment, detects abnormalities in time, prevents malfunctions, and ensures smooth production.